GCP – Automating smartphone manufacturing with Visual Inspection AI

AI technologies can help organizations keep up with their customers’ fast-changing demands and gain an edge over the competition.

For manufacturers, AI promises benefits at every level of the value chain as they try to speed up production while maintaining high-quality products. AI has proven especially beneficial for improving product quality, lowering costs, predicting equipment maintenance, avoiding unplanned downtime, and empowering employees to work smarter.

FIH Mobile, one of the world’s largest mobile phone and wireless communication device manufacturers, met with the Google Cloud team to learn more about how Google Cloud Visual Inspection products, including AutoML Vision, could help them improve product quality in their manufacturing process.

Manufacturing under increasing and extreme pressure

FIH Mobile has undergone significant change in response to factors like increased consumer and business demand and the emergence of driver assistance and infotainment technologies, IoT, and 5G. Established in April 2002 and listed on the Hong Kong Stock Exchange in 2005, FIH Mobile is a leader in the worldwide mobile device industry. The company has 71,000 employees and generated revenue of $14 billion in 2019. FIH Mobile offers vertically integrated, end-to-end design, development and manufacturing services spanning handsets, mobile and wireless communication devices, and consumer electronics products.

Moving into the internet era, FIH Mobile leveraged its core strengths in hardware and software to enter the 5G, AI, IoT, and IoV (Internet of Vehicles) fields, building a full internet and mobile ecosystem.

FIH Mobile’s business is heavily influenced by changes to downstream demand and upstream supply, both of which experienced disruption during the COVID-19 pandemic. For instance, consumers now spend less in some markets, while supply chain fluctuations hampered material availability to make components for smartphones and other devices. In an industry that already faces tough requirements for delivering top quality products under short production timelines and tight budgets, efficiency is critical.

Quality control processes prone to unreliability

FIH Mobile identified defect minimization as a potential area to start applying AI technologies in their operations. Machine learning’s ability to improve through experience presented an enormous opportunity to enhance the quality of FIH Mobile products while also optimizing processes and reducing costs.

During the smartphone manufacturing process, each printed circuit board (PCB) is inspected for defects that could compromise the final product’s quality. In the original process, FIH Mobile relied on human eyes to spot flaws in the pre-production process before components and devices moved to the next stage.

However, the number of unfound defects divided by the number of all defective PCBs—known as the defect escape rate—was a worrisome 40%. Furthermore, defect detection rates varied based on the individual doing the job, making the process susceptible to human error and subjective judgment.

AutoML Vision detects mobile defects faster and more accurately than the human eye

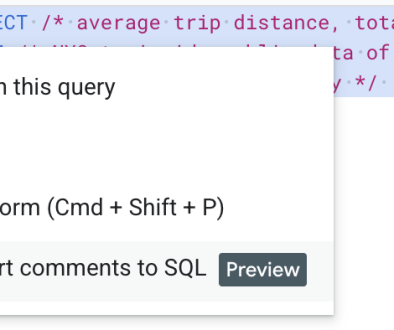

FIH Mobile proceeded to build and deploy an automated system based on AutoML Vision in April 2020. They trained machine learning models to support an image capture instrument made up of two microscopes and an X-Y table that moves printed circuit board components through the defect detection process. Each model supports software that reviews and classifies each component in the image as “Pass” or “Fail.” In total, the system checks a set number of components in each phone.

“With AutoML Vision, we can reduce our defect escape rate to 10%, while the time to inspect each component decreased dramatically to 0.3 seconds, or 1.3 seconds once fixture movement time is taken into account,” says Sabcat Shih, Senior Engineer, FIH Mobile. “In addition, all our inspection stations apply the same inspection criteria, ensuring consistency and improving confidence.”

AutoML Vision enables teams to train custom machine learning models to classify images based on labels they define and build custom models to classify images at the edge to trigger actions based on local data. With AutoML Vision, FIH Mobile can label data efficiently to maximize model performance. They simply prepare the data, label it as accurate, and let the system handle the rest.

The company is also evaluating how other Google Visual Inspection products can provide a seamless pipeline from the image output to a machine learning model.

As AI adoption continues to be a game-changer across every industry, manufacturing is primed for a revolution. We look forward to supporting our customers as they continue to find new ways to innovate with AI. To learn more about how you can use our vision products for visual inspection and other use cases, check out Google Cloud Vision AI.

Read More for the details.