GCP – AI infrastructure is hot. New power distribution and liquid cooling infrastructure can help

AI is fundamentally transforming the compute landscape, demanding unprecedented advances in data center infrastructure. At Google, we believe that physical infrastructure — the power, cooling, and mechanical systems that underpin everything — isn’t just important, but critical to AI’s continued scaling.

We have a long-standing partnership with the Open Compute Project (OCP) that has been instrumental in driving industry collaboration and open innovation in infrastructure. At the 2025 OCP EMEA Summit today, we discussed the power delivery transformation from 48 volts direct current (VDC) to the new +/-400 VDC, which will enable IT racks to scale from 100 kilowatts up to 1 megawatt. We also shared that we’ll contribute our fifth-generation cooling distribution unit, Project Deschutes, to OCP, helping to accelerate adoption of liquid cooling industry-wide.

- aside_block

- <ListValue: [StructValue([(‘title’, ‘Try Google Cloud for free’), (‘body’, <wagtail.rich_text.RichText object at 0x3e6ec45ea7c0>), (‘btn_text’, ‘Get started for free’), (‘href’, ‘https://console.cloud.google.com/freetrial?redirectPath=/welcome’), (‘image’, None)])]>

Transforming power delivery with 1 MW per IT rack

Google has a long history of advancing data center power delivery. Almost 10 years ago, we championed the adoption of 48 VDC inside the IT rack to significantly increase the power distribution efficiency and reduce losses compared to what typical 12 VDC solutions delivered. The industry responded to our call to action to collaborate on this technology, and the resulting architecture has worked well, scaling from 10 kilowatts to 100 kilowatts IT racks.

The AI era requires even greater power delivery capabilities for two distinct reasons. The first is simply that ML will require more than 500 kW per IT rack before 2030. The second is the densification of each IT rack, where every millimeter of space in the IT rack is used for tightly interconnected “xPUs” (e.g. GPUs, TPUs, CPUs). This requires a much higher voltage DC power distribution solution, where power components and battery backup are outside of the IT rack.

We are excited to introduce +/-400 VDC power delivery that can support up to 1 MW per rack. This is about much more than simply increasing power delivery capacity — selecting 400 VDC as the nominal voltage allows us to leverage the supply chain established by electric vehicles (EVs), for greater economies of scale, more efficient manufacturing, and improved quality and scale, to name a few. As part of the Mt Diablo project, we are collaborating with Meta, and Microsoft at OCP to standardize the electrical and mechanical interfaces, and the 0.5 specification draft will be available for industry feedback in May.

The first embodiment of this work is an AC-to-DC sidecar power rack that disaggregates power components from the IT rack. This solution improves the end-to-end efficiency by ~ 3% while enabling the entire IT rack to be used for xPUs. Longer term, we are exploring directly distributing higher-voltage DC power within the data center and to the rack, for even greater power density and efficiency.

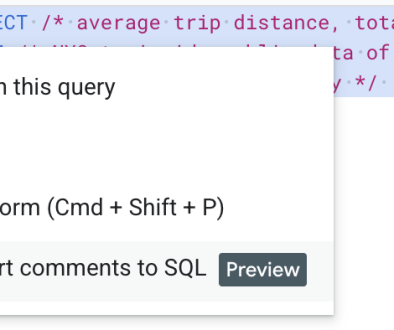

+/-400 VDC power delivery: AC-to-DC sidecar power rack

The liquid cooling imperative

The dramatic increase in chip power consumption — from 100W chips to accelerators exceeding 1000W — has made advanced thermal management essential. Packing more powerful chips into racks also creates significant challenges for cooling density. Liquid cooling has emerged as the clear solution, given its superior thermal and hydraulic properties. Water can transport approximately 4000 times more heat per unit volume than air for a given temperature change, while the thermal conductivity of water is roughly 30 times greater than air.

At Google, we’ve deployed liquid cooling at GigaWatt scale across more than 2000 TPU Pods in the past seven years with remarkable uptime — consistently at about 99.999%. Google first used liquid cooling in TPU v3 that was deployed in 2018. Liquid-cooled ML servers have nearly half the geometrical volume of their air-cooled counterparts because they replace bulky heatsinks with compact cold plates. This allowed us to double chip density and quadruple the size of our liquid-cooled TPU v3 supercomputer compared to the air-cooled TPU v2 generation.

We’ve continued to refine this technology generation over generation, from TPU v3 and TPU v4, through TPU v5, and most recently, Ironwood. Our implementation utilizes in-row coolant distribution units (CDUs) with redundant components and uninterruptible power supplies (UPS) for high availability. These CDUs isolate the rack’s liquid loop from the facility loop, providing a controlled, high-performance cooling system delivered via manifolds, flexible hoses, and cold plates that are directly attached to the high-power chips. In our CDU architecture, named Project Deschutes, the pump and heat exchanger unit is redundant, which is what has enabled us to consistently achieve the above-mentioned fleet-wide CDU availability of ~99.999% since 2020.

We will contribute the fifth-generation Project Deschutes CDU, currently in development, to OCP later this year. This contribution, including system details, specifications, and best practices, is intended to help accelerate the industry’s adoption of liquid cooling at scale. Our insights are drawn from nearly a decade of designing and deploying liquid cooling across four generations of TPUs, and encompass:

-

Design for high cooling performance

-

Manufacturing quality

-

Reliability and uptime

-

Deployment velocity

-

Serviceability and operational excellence

-

Supply ecosystem advancements

Project Deschutes CDU: 4th gen in deployment, 5th gen in concept

Get ready for the next generation of AI

We’re encouraged by the significant strides the industry has made in power delivery and liquid cooling. However, with the accelerating pace of AI hardware development, it’s clear that we must collectively quicken our pace to prepare data centers for what’s next. We’re particularly excited about the potential for rapid industry adoption of +/-400 VDC, facilitated by the upcoming Mt Diablo specification. We also strongly encourage the industry to adopt the Project Deschutes CDU design and leverage our extensive liquid cooling learnings. Together, by embracing these advancements and fostering deeper collaboration, we believe the most impactful innovations are still ahead.

Read More for the details.