GCP – TELUS: Solving for workers’ safety with edge computing and 5G

Editor’s note: In February 2021, Google Cloud and TELUS announced a 10-year strategic alliance to drive innovation of new services and solutions across data analytics, machine learning, and go-to-market strategies that support digital transformation within key industries, including communications technology, healthcare, agriculture, and connected home. By December 2021, TELUS had completed a pilot for a use case that leveraged Google Cloud AI and Machine Learning solutions and Telco Edge Anthos to increase safety in the workplace and save lives in manufacturing facilities. The use case leverages Multi-Access Edge Computing (MEC) to move the processing and management of traffic from a centralized cloud to the edge of TELUS’ 5G network, making it possible to deploy applications and process content closer to its customers, and thus yielding several benefits including better performance, security, and customization. Today, we invite Samer Geissah, Head of Technology Strategy and Architecture at TELUS, to share how the company is delivering on its promise to use this technology to drive meaningful change, starting with workers’ well-being.

Whenever a new technology buzzword comes along I think: what problems does this solve, and for whom is this going to make a real difference? That’s because at TELUS, we see innovation as a means to act on our social purpose to drive meaningful change, from modernizing healthcare and making our food supply more sustainable, to reducing our environmental footprint and connecting Canadians in need. Multi-Access Edge Computing (MEC) is a buzzword that offers an opportunity to do just this. That’s why we want to leverage cloud capabilities and optimize our network’s edge computing potential, tapping into our award-winning high-speed 5G connectivity to help solve some of industry’s most complex challenges.

The reason why this presents such a great opportunity is that companies across industries still rely on maintenance-heavy on-premises systems to manage core computing tasks. But, with cloud capabilities delivered at the edge of our 5G network, we open a new world of possibilities for them. For example, manufacturers who currently rely on IoT-enabled equipment in their facilities can deliver new experiences by running advanced AI-based visual inspections directly from 5G-enabled devices–all without the need for local processing power or extra on-site space. In fact, it’s this example that inspired our new use case, where our Connected Worker Safety solution can be applied across a range of business verticals to help improve safety, prevent injury, and save lives, demonstrating how the perfect combination of skilled people and digital technology can make the world a safer place.

Empowering intelligent decision making at the edge

Be it a farm, manufacturing facility, hospital, or a factory floor, workers should be able to work in environments where their health and safety are held as the highest priority. But how can employers ensure that their remote, frontline, and in-office employees are safe and healthy at all times? We’ve found the answer by combining Google Cloud AI/ML capabilities and Anthos as a platform for delivering workloads, with our network’s infrastructure.

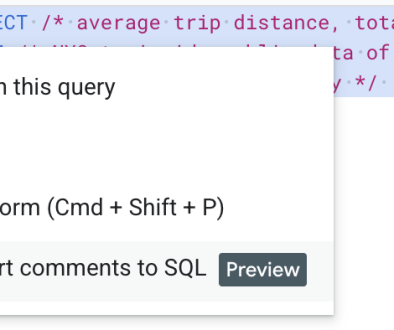

Together with Google Cloud, we have been leveraging solutions with the power of MEC and 5G to develop a workers’ safety application in our Edmonton Data Center that enables on-premise video analytics cameras to screen manufacturing facilities and ensure compliance with safety requirements to operate heavy-duty machinery. The CCTV (closed-circuit television) cameras we used are cost-effective and easier to deploy than RTLS (real time location services) solutions that detect worker proximity and avoid collisions. This is a positive, proactive step to steadily improve workplace safety. For example, if a worker’s hand is close to a drill, that drill press will not bore holes in any surface until the video analytics camera detects that the worker’s hand has been removed from the safety zone area.

A few milliseconds could make all the difference when you are operating heavy equipment without guards in place. So, to power the solution’s predetermined actions with immediate response times, we worked with Accenture and hosted the application on an Anthos bare metal Google Cloud environment running on our TELUS multi-edge access computing.

Because all the conditions in our model are programmable, this solution can be replicated at scale across a variety of practical scenarios other than factory floors. The actions in response to the analysis are also programmable, which means companies can use this technology to look at workers’ conditions and decide the best course of action to educate, assist, and protect them. All this is done through a single pane of glass ecosystem, making it easy to customize this solution to meet various business needs.

Meanwhile, leveraging our existing global networks to process data and compute cycles at the edge eliminates the need to transport data to a central location for real-time computation. This means that we can offer this solution to partners while optimizing latency and lowering costs.

Powering blink-of-an-eye communication with Anthos

To put the importance of lowering speed into perspective, consider that the average latency of blinking your eye is about 300 milliseconds. From a safety point of view, preventative processes need to be much faster than that. For this use case, our machine learning models running on edge are currently processing data at a tenth of the time it takes for you to blink your eyes, and we’re aiming to lower that latency further to help build even safer systems.

Our plan is to deploy Anthos clusters on bare metal to our customers across Canada to take advantage of our existing enterprise infrastructure, making it possible for us to run our solution closer to partners and eventually enable just one millisecond of latency.

At that point, we’ll be able to power new use cases that require near real-time feedback, leaving absolutely no room for error. This could include remote surgery, platooning of fleets on autonomous vehicles, and many other cellular vehicle-to-everything (V2X) solutions that require high-speed communication for platform operators to manage remote edge fleets in far-away places.

Improving workers’ safety while enabling new sources of revenue

Although edge computing and 5G have been around for a while, we believe that use cases like this are only just starting to demonstrate the incredible speed of change and high potential that these models provide. The next step for us is to develop our workers’ safety solution and get it to market, making TELUS an early adopter of new 5G solutions at the edge that can help our business and industry partners make workplaces safer.

It’s a great win to be able to combine efforts with Google Cloud and reduce latency in a context where timing can impact and save lives, and I’m confident that workers’ safety is just the beginning of a series of industry challenges that we’ll address together.

Read More for the details.